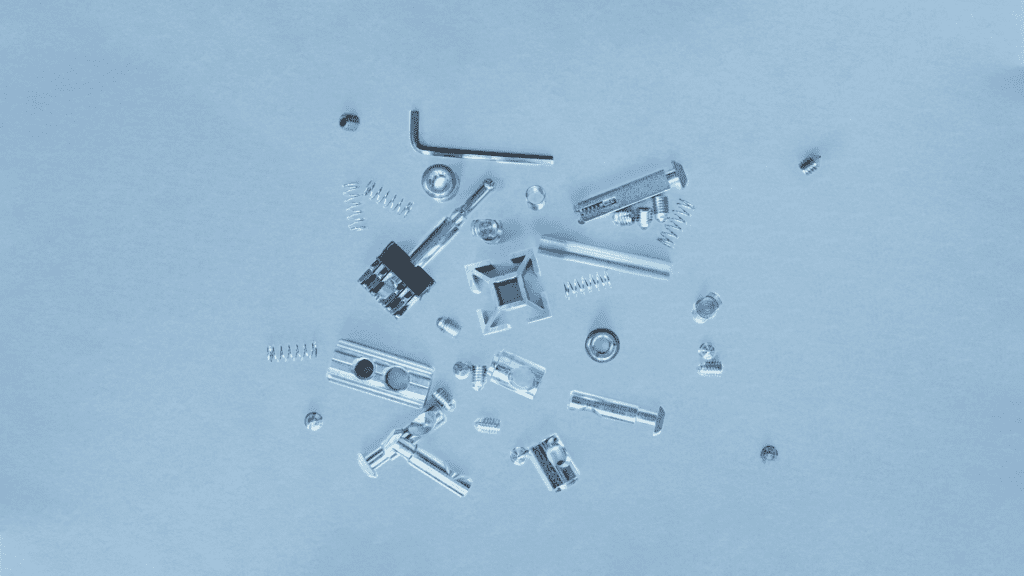

What keeps an exhibition stand stable and elegant at the same time? The answer: carefully developed fastening techniques. SYMA is particularly proud of the closures on our tried and tested profiles. Exhibitors worldwide have been able to rely on them for decades because they know that their elegance, simplicity and safety can literally be relied upon. In this blog, we present our most important connecting elements.

History and characteristics: What characterises SYMA’s closure technologies

SYMA’s core values have always been innovation, systematics and reliability. People around the world associate us with these terms. To live up to this reputation, we take no risks when it comes to the stability of our trade fair systems. This requires in particular the utilisation and consistent further development of locking technologies that are intelligent, secure and yet quick and easy to install. Modular system components from SYMA open up almost unlimited scope for their combination. The reliability and elegance of the fasteners used are the crowning glory of this creation.

The SYMA innovation of the latch lock was born back in 1991 in response to the ever faster pace of the trade fair industry. Customers were thus offered a new locking technology that makes it possible to connect frames easily, quickly and friction-locked to groove profiles from the front. The patented technology had to overcome a number of material and structural challenges to achieve its current form and function. Many of our bestsellers, such as SYMA-MOLTO, were only made possible thanks to the SYMA latch.

Let’s take a look at the three different types of our profile locking technology and their respective special features.

The uncomplicated one: Hammer bolt

Locking technology using hammer bolts or hammer heads is one of SYMA’s simplest and most flexible locking variants; The small hammer head is screwed into the respective profile, tightened and then holds each of our constructions firmly together. The clear advantage of this lock variant is the fact that the hammer bolt lock can also be used to retrofit or modify existing constructions. This is because the fastener does not necessarily have to be inserted straight, but can also be threaded into the frame at an angle without making the fastening more difficult.

The durable: latch

As already mentioned, the patented SYMA latch technology forms the basis of numerous other innovations in our range and has enjoyed great popularity for decades. The locking technology was developed for aluminium and timber frames and is available in different sizes depending on requirements.

As the name suggests, the detailed function is based on several small pawls that expand when tightened and retract again when unscrewed. In this way, an intelligent and secure fastening is achieved with just a few rotational movements, which is also extremely gentle on the material: the technology used causes fewer bulges in the supports, which supports the durability of the components used.

The extraflotte: quick release

The quick-release fastener is a particularly efficient variant of the latch fastener. This is based on the same material-friendly system. However, the latches are fully expanded with a single 180 degree turn and can therefore be fastened even more quickly. This fastener is the perfect choice for stand construction customers who want particularly fast assembly and dismantling.

Conclusion: Efficiency and safety in harmony

Closure technologies from SYMA are clearly one of our company’s greatest strengths. Customers appreciate their inspiration, creativity and reliability, just as they do with our other system components. The harmonious interplay of customised design and sophisticated technology proves to be a successful recipe for our globally sought-after services. Do you have any further questions about our locking systems, profiles or other products? Would you like a personal consultation to address your individual needs? Our experienced experts look forward to hearing from you.